Examine This Report on Aws Cwi

Examine This Report on Aws Cwi

Blog Article

The Basic Principles Of Aws Cwi

Table of Contents6 Simple Techniques For Aws CwiThe Definitive Guide for Aws CwiThe 9-Second Trick For Aws CwiNot known Facts About Aws CwiThe 20-Second Trick For Aws Cwi

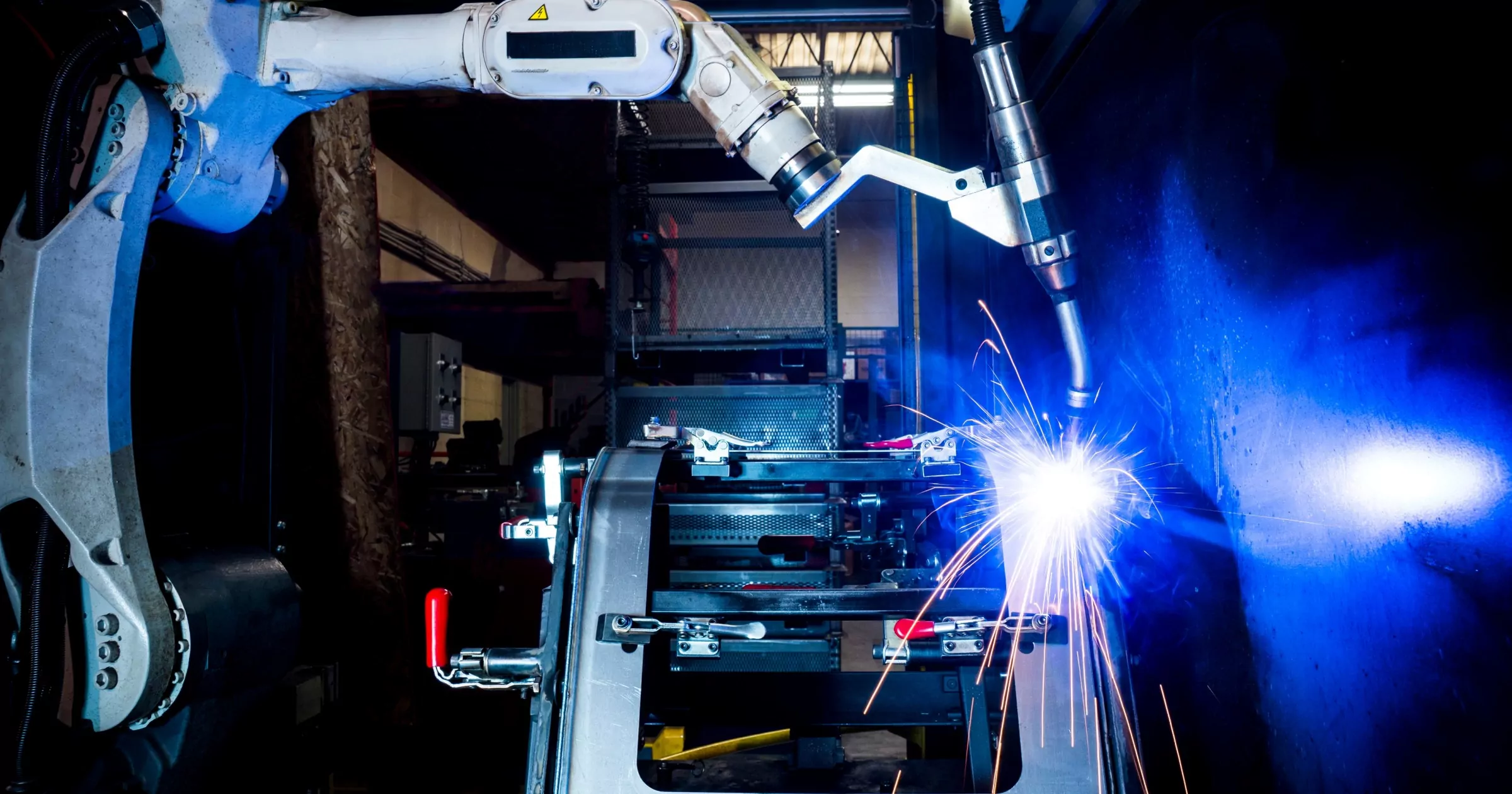

Third-party quality assurance examination of steel manufacture centers on welding examination, in addition to assessment of bolting and paint of architectural steel. KTA's steel inspectors provide Quality assurance (QC) inspectors to supplement producer's/ contractor's internal QC personnel and on tasks that mandate keeping the solutions of a qualified assessor (e.g., CWI) employed by an independent assessment firm.Inspectors perform visual inspections of material for conformance with the authorized specs, plans and codes, along with verification of Licensed Material Examination Reports (CMTR) for materials utilized. Materials and components are observed at bottom lines along the production process in both steel mills and steel construction shops. KTA's licensed welding inspectors also witness welder and welding treatment qualification tests as appropriate to the range of the task.

Steel construction examination services also consistently consist of carrying out non-destructive testing (NDT), also recognized as non-destructive assessment (NDE), consisting of Magnetic Bit Evaluating (MT), Ultrasonic Screening (UT) and Liquid Penetrant Evaluating (PT). KTA's assessment services include layer evaluations covering surface area preparation, paint, galvanizing, and metalizing.

KTA's approach is to react promptly to clients' demands, match the best inspector to the job, and provide the requisite documents. KTA has the support workers to supply technological consulting to the field employees and to the customer. KTA has professionals offered to speak with on welding, NDT and coatings.

Come sign up with an outstanding team in an exciting, fast paced, and ever-growing industry! We are seeking a CWI's and/or NDT Degree II licensed Welding Inspectors from in and around the Lithia Springs, GA location!

Aws Cwi Fundamentals Explained

Ideal candidate will certainly have high purity piping evaluation experience. CWI's and NDT Level II's extremely urged to apply.

Pro QC's third-party welding assessment services consist of: Record Evaluation Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Screening (NDT) Others Our welding examination reports are delivered within 24-hour and record all inspection points pertinent to quality, including all determined weld imperfections and electronic photos (Welding Inspection Company) (https://www.reverbnation.com/awscw1w3lding). Pro QC's group of examiners delivers third-party welding evaluations around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the UK, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and lots of even more countries

Assessment of the welding job is critical for proper quality When your business is handling major tasks with requirements for 3rd party independent welding assessment, we provide outstanding welding witness inspection services to validate that welding has actually been done according to the majority of applied welding criteria and specifications. AQSS does welding go to website inspection services for clients from a variety of sectors.

The Best Guide To Aws Cwi

Not following effectively qualified welding treatments often results in a weld of substandard top quality, which can enhance the manufacture's probability of failure under intended solution problems. By inspecting for defects, our assessors can help customers guarantee that their welds satisfy appropriate criteria of high quality assurance (AWS CWI). Weld assessments are performed for several reasons, one of the most common of which is to establish whether the weld is of appropriate quality for its intended application

The code and standard made use of relies on the industry. Our welding inspectors have actually the called for qualifications with years of experience with assessment and recognize with the majority of used welding criteria and specifications. AQSS has CWI licensed inspectors. We do these services making use of a selection of nondestructive screening (NDT) methods: The inspection is executed in conformity with pertinent codes, such as American Welding Society (AWS), American Society of Mechanical Designers (ASME), and Military (MIL-STD) basic specs.

Aws Cwi - Questions

Typically, our examiners are checking for fractures, pits, surface area pores, undercut, underfill, missed out on joints, and other elements of the weld.

Examples can additionally be taken at intervals throughout the manufacturing process or at the end of the run. Damaging screening samples are exactly cut, machined, ground, and polished to a mirror-like surface. An acid etch is after that used to aesthetically bring out the weld, and the sample is then inspected under a microscopic lense.

Report this page